|

The CORTIR III Project: Cost and Risk and Trailing Edge Innovative Reinforcement (pr. no. 640232-511715)

This project headed by Bladena is a continuation of CORTIR Phase II, with a primary focus in minimizing Operational Expenditure (OPEX) of wind turbine blades and maximizing the Annual Energy Production (AEP) of wind turbines, using a risk based approach. The CORTIR III project is supported by the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency. |

Motivation

The increase of the blade length increased the loads due to their increased weight and length of the blade. The most important loads, as seen in previous EUDP projects, for long, modern blades are torsional loads. Torsional loads are closely connected with localized deformations and increased bond line peeling stresses.

Wind turbine blades are one of the most expensive components of the turbine and are crucial for revenue generation. Therefore, further investigation into how this component can become more reliable than today is essential.

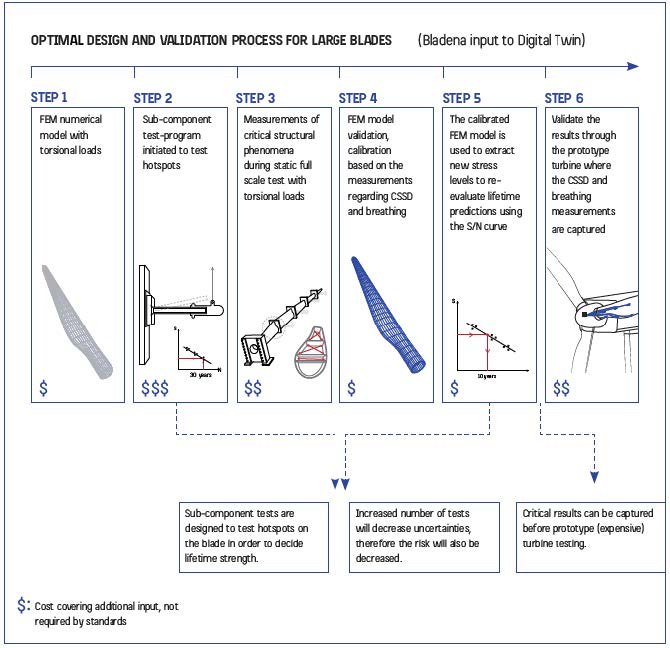

One way to improve the reliability of long blades is to create and validate more accurate numerical structural analysis tools, and extend and convert modeling results to risk indices, which can be utilized to form a holistic overview of the structural performance of the wind turbine blade from an economical perspective. The validation campaign can be performed by adopting a multi-scale approach, where tests are carried out on sub-components, large-scale as well as in-field testing by measuring structurally relevant deformations (e.g., panel breathing, cross-sectional shear distortion). Through such validation approach of the models, the lifetime of the blade can be predicted more accurately, and relevant actions can be taken.

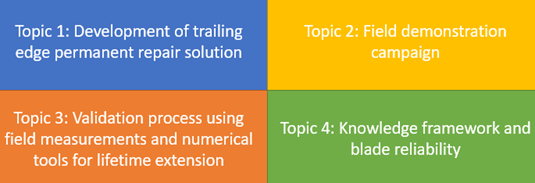

Such actions could include reinforcing the trailing edge, thus making it more durable to the high loads and reducing potential defects in that area. Existing repair solutions are temporary actions that do not eliminate the root-cause; hence the defects reoccur. Other actions might include monitoring of the region for crack activity in the bond lines, which can give indication of damage propagation if such exists. The project is divided into the following 4 topics.

Wind turbine blades are one of the most expensive components of the turbine and are crucial for revenue generation. Therefore, further investigation into how this component can become more reliable than today is essential.

One way to improve the reliability of long blades is to create and validate more accurate numerical structural analysis tools, and extend and convert modeling results to risk indices, which can be utilized to form a holistic overview of the structural performance of the wind turbine blade from an economical perspective. The validation campaign can be performed by adopting a multi-scale approach, where tests are carried out on sub-components, large-scale as well as in-field testing by measuring structurally relevant deformations (e.g., panel breathing, cross-sectional shear distortion). Through such validation approach of the models, the lifetime of the blade can be predicted more accurately, and relevant actions can be taken.

Such actions could include reinforcing the trailing edge, thus making it more durable to the high loads and reducing potential defects in that area. Existing repair solutions are temporary actions that do not eliminate the root-cause; hence the defects reoccur. Other actions might include monitoring of the region for crack activity in the bond lines, which can give indication of damage propagation if such exists. The project is divided into the following 4 topics.

Validation process and field measurement campaign

|

The lack of quantification methodologies in determining the effects of torsional loads result in increased OPEX due to downtime because of unexpected repair campaigns. When it comes to offshore wind turbines, where the access is limited compared to onshore sites, and as the limitations on vessel availability and weather conditions is also limited, the downtime issues are more challenging and the OPEX costs are much higher. As both the failure rate, due to larger, heavier blades installed in offshore sites, and the consequent cost of downtime are inflated in offshore wind farms, there is a need to both reduce the uncertainty during the design phase for future blades and to develop a permanent solution that mitigates trailing edge issues for blades in operation.

This track of the project will focus on assisting the validation process by field measurements during operation. The chosen approach is to use the collected measurements from the first phase of the field demonstration. The methodology followed during the project will initially include re-engineering of the FEM model of the selected blade. FEM simulations will provide the baseline in terms of out-of-plane deformations, which will then be compared to the real field measurements. |

This project headed by Bladena aims with the assigned consortium to work together in defining and finally implementing the validation process towards an increased reliability level of wind turbine blades. The aim of the project is to decrease the LCoE, by using existing academic research and technology to increase the benefit for the WTOs.

Trailing Edge Innovative Reinforcement

|

The trailing edge of a blade, especially in the max chord and root transition zone regions, are the most vulnerable areas of a blade. Even though the mid-span region is part of the aerodynamic section of the blade, trailing edge splits can occur due to the increased buckling. Failures in bondlines and cracks along the trailing edge are occurring either due to imperfections or flaws during the manufacturing processes or due to the increased edgewise fatigue loads in longer blades. For blade designs with large flatback trailing edge, the adhesive bondline in the corners are specifically more vulnerable due to the high bending of the pressure side panel. As a mitigation, solution to reinforce the trailing edge is needed.

|

The proposed retrofit solution prevents panel movement during operation, resulting in less stresses on the trailing edge bond lines in the transition zone and max chord regions, and decrease buckling capacity in the mid-span area, with less damages occurring in these regions of the blade. The installation process will require drilling through the trailing edge panels, which at first might raise a concern to potential users. It is therefore of importance to demonstrate that such drillings in the trailing edge panels are harmless for the operation of a blade. The demonstration process will include both FEM studies and experimental laboratory testing on sub-component specimens and a large-scale section, which will showcase that the strain levels around the drilled region of the blade are acceptable and will eventually remove this concern.

Knowledge Framework and Reliability

|

An additional aim of this project is to establish a framework that ensures that the knowledge gained through any relevant activity is utilized by the WTOs to a level that improves the understanding of the industry concerning wind turbine blades and their structural issues. Inspired by more mature industries, e.g., Civil Engineering, Aircraft, Naval Architecture and Oil & Gas, such as a knowledge framework can be established by following similar methodology but adjusted to the specific pre-requisites in the wind energy industry.

As blades grow larger, the need of realistic f remaining lifetime prediction of a blade is increasing. The “expected” 20-30 year lifetime stated by the manufacturers is in many cases not realistic as this claim is not validated through sufficient test campaigns. Failure mode drivers have kept changing historically, with torsional loads being one of the new main drivers for the current commercially available blades, changing the currently occurring failure modes compared to what was occurring a decade ago. Therefore, the approach both in the design phase and in the decision-making regarding the operation and maintenance strategies is a dynamic process which has no guidelines set in stone over the years. |

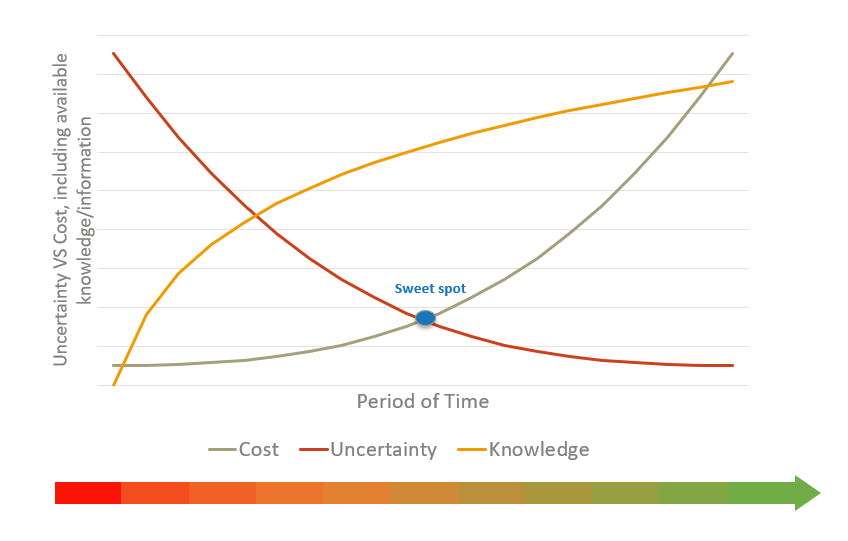

The unused available knowledge is believed to have the potential to further decrease the operation and maintenance costs of a WTO’s fleet, by reducing the uncertainty in assumptions and estimations when the reliability of a blade is calculated. However, there is a limit as to how much the uncertainty can be reduced, before the available knowledge becomes too costly to obtain, see Figure 6. The more the uncertainty is desired to be reduced, the more costly this process will be. Hence, the “sweet spot” represents the optimal level in which both the uncertainty and the cost should remain in order to optimize the reduction of risk. This aspect will also be investigated in the project.

Related projects

|

CORTIR - (Cost and Risk Tool for Interim and preventive Repair)

The project aims to cope with the various challenges of the appropriate operation and maintenance strategies. A Cost and Reliability Tool (CAR Tool) will be developed. The vision of this project is to make the decision-making process regarding operation and maintenance decisions easier and to support the entire value chain on how to minimize risk, operation and maintenance cost. |

CORTIR Phase II - Cost, Risk and Transition zone Innovative Reinforcement

The main deliverables are a new retrofit solution designed for high forces in the Root-Transition Zones (RTZ) of blades, a new innovative state-of the art operation and maintenance strategy and lastly further developments of the Cost and Risk Tool (CAR Tool). |