About

|

Jr. nr. 64016-0121

The purpose of this project is to establish demonstration, develop solutions fit for market and prove through a series of sub-component tests and on a 7MW off-shore turbine that the technology is ready for market introduction. The outcome of the project will be cost effective product for retrofit and new design. The project is an integrated part of a European consortium “DemoWind 2 ERA-NET CoFund Action” with the purpose of delivering cost reduction in Offshore Wind. The X-DOF project is supported by the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency. |

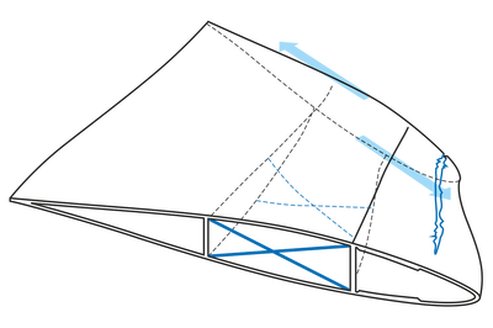

X-Stiffener™The X-Stiffener™ prevents longitudinal cracks on the leading edge of the blades. Longitudinal cracks on the leading edge are very often found after only a few years of operation. The X-Stiffener™ connects the two sides of the blades like a cross in a bookshelf. Experimental and theoretical modelling has proven that the X-Stiffener™ significantly reduces the twisting and hence the peeling stresses are reduced to non-critical levels.

|

Related projects

CORTIR - (Cost and Risk Tool for Interim and preventive Repair)

The project aims to cope with the various challenges of the appropriate maintenance strategies. A Cost and Reliability Tool (CAR Tool) will be developed. The vision of this project is to make the decision-making process regarding maintenance decisions easier and to support the entire value chain on how to minimize risk, operation and maintenance cost. |

RATZ - (Root Area and Transition Zone)

The aim of this project is to demonstrate and develop a retrofit solution, the Floor™ (a Bladena patent), for avoiding crack development due to edgewise loading of the blade. The project address a serious problem seen in the field, which pose an extensive operation and maintenance cost for the wind turbine owners. |