|

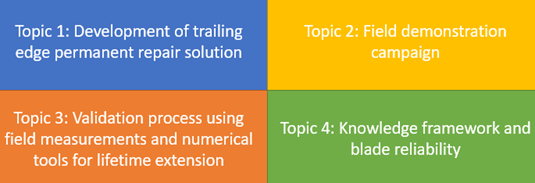

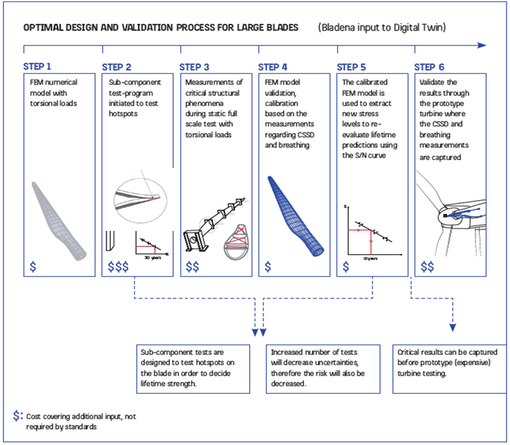

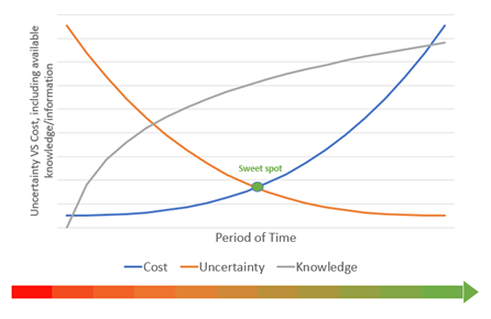

Having successfully completed four major research projects (CORTIR II, CORTIR, RATZ and LEX), Bladena has been successful in continuing the collaboration with EUDP and 24 companies in a new 2-years project called CORTIR Phase III. The partners cover the entire value chain involving 18 wind turbine owners (WTO), 1 independent service provider (ISP), 1 manufacturer (OEM), 1 insurance company, 1 independent consultancy as well as 2 Danish universities.  Partners are: Bladena, AAU Civil Engineering, DTU Construct, Global Wind Service, TÜV SÜD Denmark, Codan, Nordex, Engie, Shell, Statkraft, Northland Power, SR Energy, ScottishPower, EDF Renewables, TOWII, Equinor, SSE Renewables, Galp Energia, WindMW, Arise, Skellefteå Kraft, Sahara Wind, ENEL, European Energy, OX2 Project scope The main deliverables of the project are an innovative trailing edge reinforcement to remove the root cause of trailing edge split failures, a field measurement campaign, a sub-component level test campaign focusing on specific failure modes, a thorough Validation Process, and the application of the damage tolerance approach similar to other industries (civil engineering, naval architecture, aircraft, oil and gas) in order to increase blade reliability. Bladena and partners have a budget of 2.8 mill. Euro to deliver the results within the 2-year project framework. As the wind industry is continuously growing, so are the wind turbines. With increasing blade lengths structural failures of the blades become a significantly higher technical as well as financial risk, resulting in increased cost for repair and loss of Annual Energy Production (AEP). In many cases, the blades’ actual lifetime is far shorter than it is predicted once commissioned into operation. One of the critical structural issues of large (+60m) wind turbine blades is trailing edge splits, frequently for blades with large flatback trailing edge profile where corner bondlines can be found. This failure mode is today occurring more frequently due to significantly increased fatigue peeling stresses in the adhesive bondlines. A field measurement/demonstration campaign will complement the development of the solution. Shell, as one of the management steering group members of the project, will provide an operational turbine to perform in-field measurements, focusing on out-of-plane panel deformation. During the measurement campaign, Global Wind Service and Nordex will support Bladena in the installation of the equipment. Value for partners and the wind industry

The measured in-plane strengths are in such high ranges that it is not possible to experience in-field. As part of the CORTIR III project, a sub-component level test is designed to demonstrate the impact of panel bending on specific failure modes rather than in-plane strength or wrinkles. During the 2-year project period, a large number of whitepapers will be released to further mature the industry which all will be paired with an online webinar free to attend for anyone who is interested. Kick-off seminar and acknowledgement On the 21st of March 2024, Bladena successfully hosted the kick-off seminar for the CORTIR III project. During the event 16 of the partner companies were represented with a total of 25 participants. We would like to say thank you to all attendees of the fruitful seminar and also the partners who could not make it to the kick-off event for their support. A great thanks also goes to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (Energistyrelsen part of Klima-, Energi-, og Forsyningsministeriet) for funding the CORTIR Phase III project.

For further information please contact CORTIR Phase III Project Manager, Bladena’s CEO, Find Mølholt Jensen at [email protected]. Comments are closed.

|

Archives

July 2024

|