|

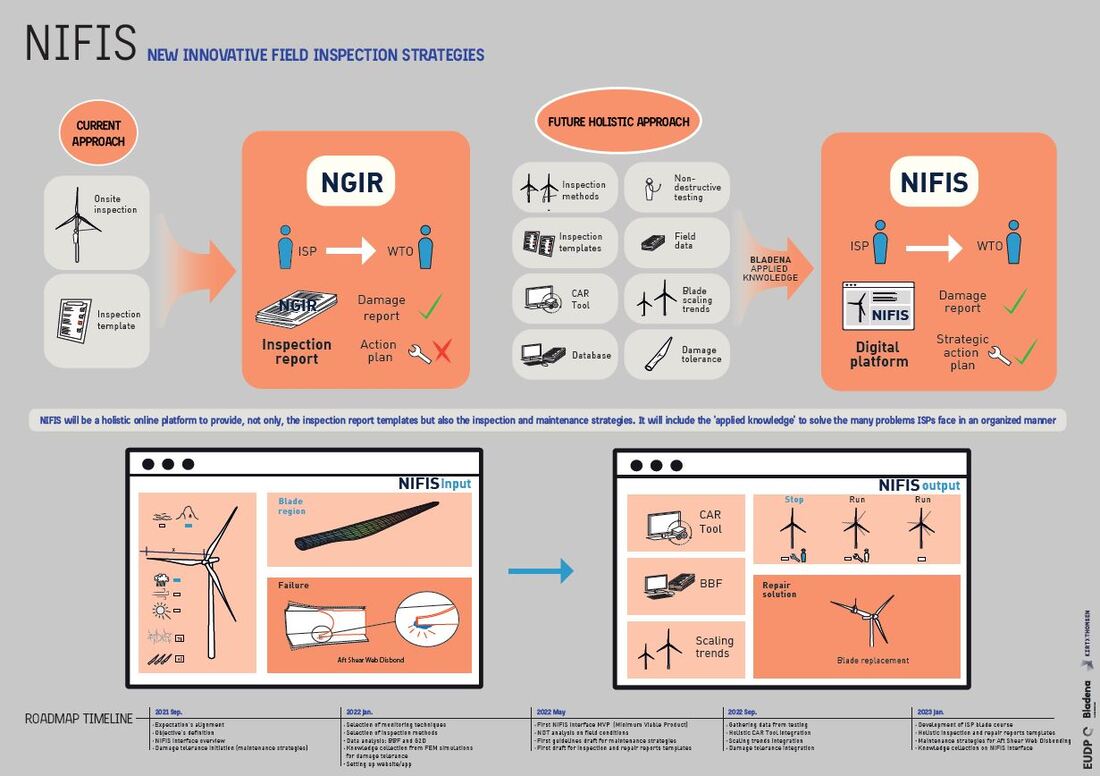

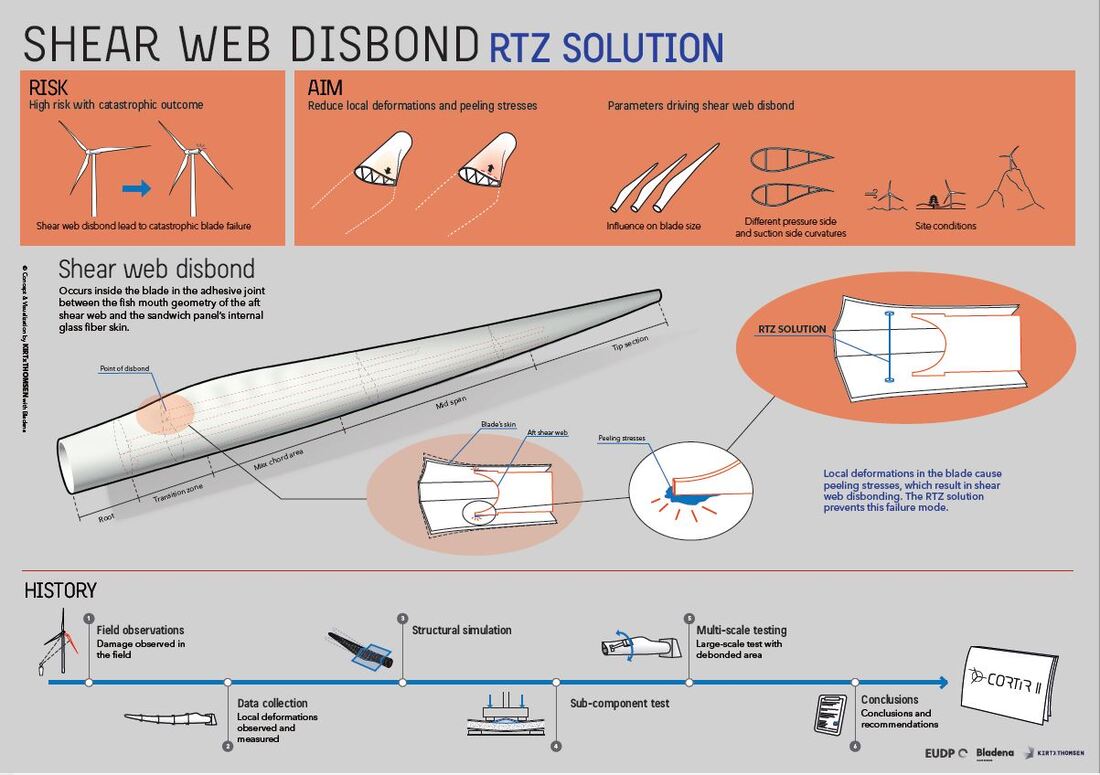

Yesterday, Bladena and 25 partners from the wind industry kicked off a new EUDP project called CORTIR Phase 2. Uniquely for this project, 5 Independent Service Providers (ISPs) have joined the project to help develop a new software tool and a new retrofit repair solution that will provide ISPs with a competitive advantage in the after-market enhancing their services towards Wind Turbine Owners. The CORTIR Phase 2 project focuses on a critical structural blade issue on +60m long wind turbine blades that will increase in the future. In short, in technical terms, the issue is a debonding of the shear web from the load-carrying spar caps in the root-transition zone meaning that a blade with this type of failure will have a higher risk of a collapsed blade. To foresee and prevent this type of damage Bladena together with 26 partners (15 WTOs, 5 ISPs, 1 Insurance Company, 2 Universities, 1 OEM, and 2 R&D companies) met at the kick-off Seminar on the 22nd of September to discuss the planning and developments of the two main objectives – a New Innovative Field Inspection Strategy (NIFIS) Platform and the development of a Root-Transition Zone (RTZ) retrofit solution. NIFIS – A software tool that helps ISPs determine the best inspection strategy for blade Depending on a crack’s location and size, the blade type, and blade length, to name a few, this will have a huge impact on what actions to take to prevent it from progressing. Based on the situation the software tool will be able to show ISPs what to inspect, and the position. Furthermore, the ISP and/or the WTO will have an instant recommendation on what action to take onsite. In some cases, the recommendation will be to continue running the turbine but do more frequent inspections. By having ISPs to help build the software tool it will become customized to fit their daily practical work taking structural, cost, and risk knowhow into consideration. RTZ Retrofit Solutio Many ISPs only have a limited set of options to offer the WTOs and the competition in the service market is high. The main competitive factor for an ISP is to be able to offer the market a reliable cost-efficient retrofit solution for the increasingly critical damage problems. As of yet, no repair solution has proven more than temporary. Therefore, this failure mode has become a significant risk for the industry, especially for large offshore wind turbines, where limited access may result in the necessity for significantly extended periods of downtime and consequently AEP losses. Through the next 2 years, the aim is to develop and demonstrate an innovative technology of a retrofit solution to a level where it is ready to be commercialized by Bladena after the project period. The RTZ-Solution will fulfill a need in the market and will be uniquely designed for the high forces in the root-transition zone of the blades, removing the root cause of the shear web disbond failure mode and providing more reliable blades for the WTOs. Why call the project “phase 2”? In the previous project CORTIR, a Cost and Risk /decision support tool (CAR Tool) was developed to help WTOs be able to calculate different variations of O&M strategies showing the risk of each strategy. Data simulations from the CAR Tool will be used in NIFIS amongst others. The outcome of the seminar Throughout the seminar, the participants had many relevant questions about how the solutions will be developed in the project. The overall answer was that to ensure the most optimized solutions it is key that the partners bring all their knowledge and expertise to the table. Also, they talked about NIFIS and how the WTOs will be able to inspect blades daily without increasing the OPEX drastically. This will be further discussed and developed in workshops in the next two years.

In the panel discussion the WTO Blade Network Steering Group Members Nicolas Quievy, Engie, and Birgit Junker, RWE debated with partners about the future of blades and how new sustainable blades will become an increasing factor in the future. Bladena has for many years been pushing for the industry to improve the certification standards through Owners Requirements, and also here the panel sees some positive improvements as DNV is working on a project to do exactly this. Even though there were disagreements on how to go around these improvements, there was a broad consensus that if wind turbine owners are not involved in supporting the improvements of the certification standards they should get involved. A great to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program) for funding the CORTIR Phase 2 project (Cost, Risk and Transition zone Innovative Reinforcement) together with support from the whole value chain in the wind industry to reduce LCoE. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. Comments are closed.

|

Archives

July 2024

|