A new software tool can simulate cost and risk to optimize O&M strategies for wind turbine blades.3/18/2021

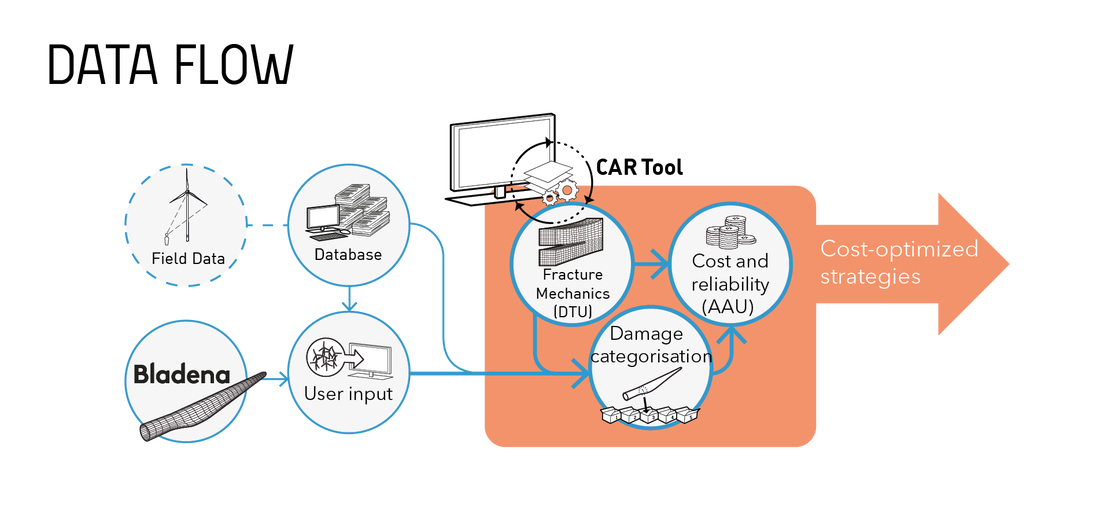

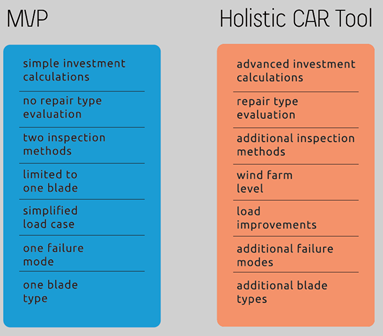

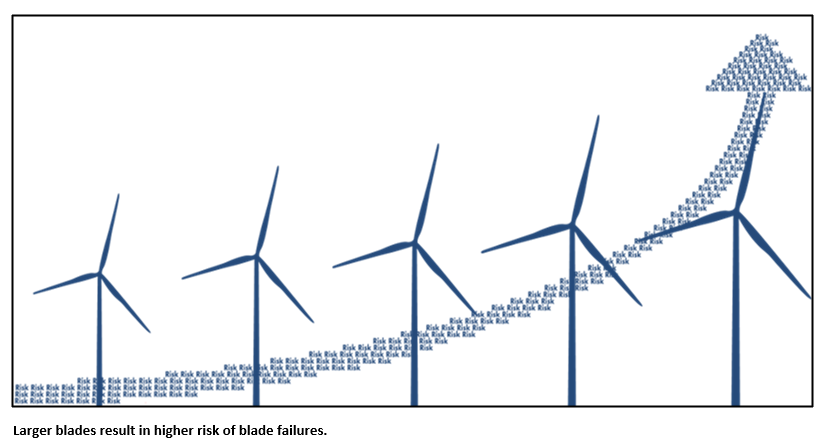

Through a 2-year project called CORTIR blade experts from the entire value chain (13 WTOs, 3 OEMs etc.) have worked hard to develop a software tool (Cost and Risk Tool) that aims to support wind turbine owners decide what optimal O&M strategy to use to minimize the risk of blade failures. Yesterday, March 17th, Bladena celebrated with partners the finalization of the project. Over the years, the size of the wind turbine blades has increased significantly. With increased blade lengths, the loads on the blades have also drastically increased giving rise to structural challenges. The rising number of damages leads to an increase in maintenance and repair costs and of the risk of energy production loss for the wind turbine owners (WTO's). The current situation in the wind turbine industry is that when damages and failures occur on blades, it is unpredictable in relation to cost and risk, unscheduled and consequently outside the operational budget. To help solve this Bladena came up with the idea to create a Cost and Risk / decision support tool (CAR Tool) focusing on blade damages. WTOs would then be able to calculate different variations of O&M strategies showing the risk of each strategy. As a result of this the CORTIR project was born in February 2019. The main objective of the CORTIR Project has since then been to develop the CAR Tool to make it ready for trial users. Already, Engie has been a successful trail user and more WTOs are interested to see the potential within their own organisation. In a CAR Tool video, developed in the project, Nicolas Quievy, Senior Wind Technology Manager at Engie states that; “The tool can have a real impact on the overall optimization of O&M in wind turbines and it will be an important step forward to preventive maintenance based on risk considerations, if the CAR Tool in the future becomes even more holistic with additional damages, erosion and lightning.” In technical terms the CAR Tool are based on fracture mechanics describing damage progression and on cost and reliability models. Field data and test data are used to calibrate the models. A Minimum Viable Product (MVP) is now in place with a set of different indexes. But the aim is not to stop here.

Therefore, one of the final messages at the Final Online Meeting was, that Bladena will aim for continuing developing the tool, if having support from EUDP and partners.

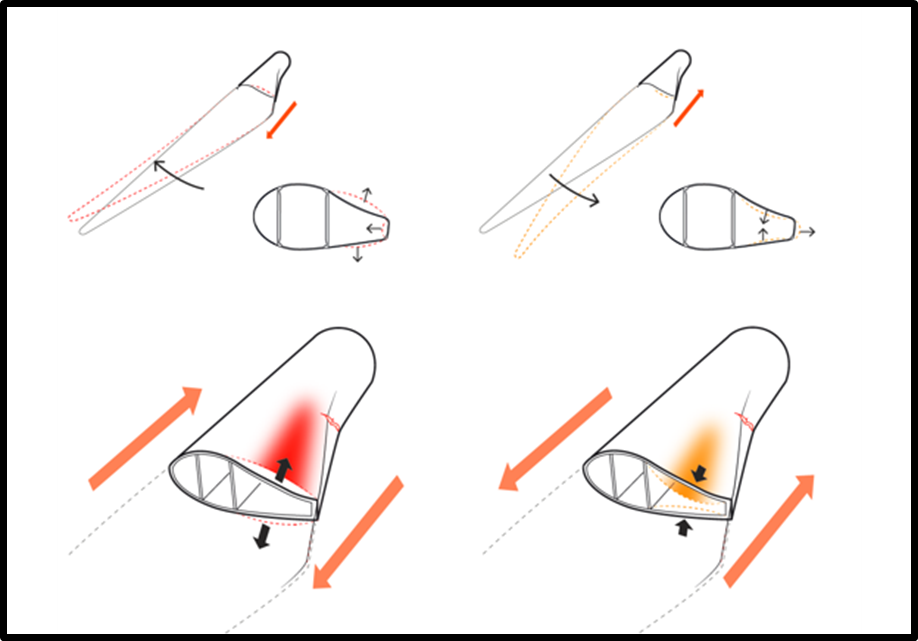

Also, a retrofit solution for the tip opening of the wind turbine blade in the tip region that is caused by lightning has also been developed in collaboration with the project partners as it is another critical failure mode that the blades often face. All results in the project are uncovered in the CORTIR Final Report and communicated through visualizations in videos, brochures, posters, The Blade Handbook and models together with Kirt x Thomsen. A great thanks also goes to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program) for funding the CORTIR project (Cost and Risk Tool for Interim and Preventive Repair) together with support from the whole value chain in the wind with the aim to reduce LCoE. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. A newly renovated quality facility with conference rooms, private parking, canteen, and new hotel options will become the new setup for Bladena’s headquarter. The brand-new office is part of “The yellow buildings”, which is placed in the vivid centre of Høje Taastrup (part of Copenhagen). The office building is located only 100 meters away from the train station, 15 minutes by train away from the main station in Copenhagen and 30minutes from the airport. Being located in the capital makes the travel back and forth from the office easier. Across the street, there is a luxurious congress centre, where Bladena will organize future quarterly seminars and workshops to meet the high request from customers and network.

Unfortunately, the Corona situation is still a serious matter. Therefore, Bladena is planning to host more online seminars as attendance from the industry has proved to be very positive. The new office building contains more meeting rooms with better equipment, which will help Bladena obtain the goal for more online meetings and seminars with better-quality equipment and execution. In early 2021, when allowed Bladena will organize a reception to celebrate the thriving growth and the expansion of the team. The new office building opens a lot of opportunities for Bladena. The office space is twice as big as the current office, which means that Bladena has more room for expansion. We are planning to expand our team with new employees quite rapidly in the coming years and if/when we need additional square metres again the building is suited for further expansion. This was the hot topic on yesterday’s Online Blade Failures Seminar where Bladena together with 27 wind turbine owner companies and CORTIR partners all shared their point of view. As more and more data show blade failures coming from the field, especially on larger blades, the topic of blade failures is more important than ever. On the 26th of November at Bladena’s Online CORTIR Blade Failure Seminar, a total of 27 different WTO-companies were present. When damages and failures occur on wind turbine blades, it is semi-unexcepted and often outside the operational budget. The associated costs for repair actions often end up as a dispute between WTOs, OEMs and Insurance companies, and risk will increase with future up-scaling of blades. In the EUDP funded project “Cost and Risk Tool for Interim and Preventive Repair” (CORTIR) the whole value chain in the wind industry is brought together to work on a new beneficial strategy to reduce LCoE. Birgit Junker, Blade Specialist from RWE and partner in the CORTIR project states: “We are seeing increasing challenges when it comes to blade failures in the field. To make drastic change the failures need to be addressed by all the players in the wind industry. The CORTIR Project is a platform where the different players can contribute with input and collaborate to bringdown LCoE”. Chaired by Bladena and with contributions from Birgit Junker from RWE, Daniel Liu from WoodMac, Nicolas Quievy from Engie, Fransisco Garcia Lopez from Enel, Hans Møller from EWII and Michael Pedersen from Ørsted, the seminar was taken to new heights. Daniel Liu from WoodMac presented statistics of the above description failure modes (current + trends). A presentation about the availability of field data and methods to apply Asset Integrity Management systems was done by Francisco Garcia Lopez from ENEL. Along with this he explained how an Asset Integrity Management System can lead to an Optimized Risk Based Maintenance.

In the afternoon session, the subject was National and International (IECRE) regulations and how to apply them as a WTO. Hans Møller from EWII and Michael Pedersen from Ørsted took part of the discussion on how they as a WTO fulfill the regulations. The annual inspection e.g. of the lightning system and the obligation to report damages were the key topics. The seminar ended with a final discussion and followed with a roundup by Find Mølholt Jensen. The goal of the Seminar and the CORTIR Project is to support the WTO’s in the decision-making process with regards to criticality of the damages they observe in the field and how to minimize the risk and O&M cost. To do so it is important to understand where the damages takes place and why the damages occur. The Cost and Risk Tool (CAR-Tool), developed through the CORTIR project, serves this purpose as it consists of fracture mechanics crack propagation models as well as cost and risk models. The next CORTIR seminar will be in Spring 2021 where the central scope of this seminar is Damage Tolerance in Blades. The CORTIR project is supported by the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program). For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. The Blade Handbook developed together with Kirt x Thomsen and partners in the CORTIR, RATZ and LEX projects was nominated as one of the finalist in the category Message understood to the Danish Design Awards. We are honored to have been a part of this and be able to show off the book which contains years of great knowledge from partners through the projects. The category Message understood can be seen here: It is now official! The Blade Handbook is one of the finalists to wind a Danish Design Award! We are proud to receive the acknowledgment on behalf of all the partners involved. Good work everyone!

To read more about the award, please go to: https://danishdesignaward.com/nominee/the-blade-handbook/ In early February 2020 Kirt x Thomsen announced that the Blade Handbook developed within the CORTIR project supported by the EUDP has been shortlisted between dozens of design solutions to be in the running of winning a Danish Design Award 2020.

The awareness and acknowledgement the Blade Handbook has received over the past couple of years is a result of hard work, clever thinking and dedication from all who have participated in developing the Blade Handbook. To present the Blade Handbook Kirt x Thomsen has created a short movie presenting the Handbook. Fruitful discussions between members of the wind turbine industry as part of the CORTIR project1/24/2020

Last week, the entire value chain of the wind industry was gathered in Denmark at the CORTIR Midterm Meeting. Here the certification body DNV GL was invited to present their take on the limitations of the current certification standards. This led to a fruitful dialog between the WTOs (Wind Turbine Owners) and DNV GL. What was planned to be a 45 minutes presentation ended up taking almost 3 hours. On the 15th and 16th of January, the entire value chain was gathered at Bladena’s offices in Roskilde, Denmark to participate in the CORTIR Midterm Meeting. In total, 15 different WTO-companies were present. Some attended as CORTIR project partners, others from the Blade Group Network which now has grown to consist of 47 WTO companies. Amongst those were owners like EDF, E.ON, Ørsted, ENEL, Equinor and more. On the first day, the certification body DNV GL was invited to speak about their take on the limitations of the current certification standards in the industry. Through the presentation, Dr. Christopher Harrison from DNV GL received a lot of questions questioning the integrity of the current standards. His response was positive and accommodating to the input received from all participants. “DNV GL appreciates collaboration from all stakeholders in the industry and plans to continue the relationships formed at the CORTIR seminar as our standards and guidelines evolve in the future,” says Christopher. After the presentation Nicolas Quievy, Technology Manager from Engie chaired the further discussion. “I was happy to chair a quite intense and fruitful session during the CORTIR Midterm Meeting. There is a common understanding that the industry can do better in reducing the lifecycle costs associated to blades by improving inspection strategies, utilizing full potential of certification standards, carrying out research projects to better assess failure modes seen in operation, etc,” says Nicolas. The discussion led to a constructive dialog on what the limitations are, how to move forward and how the WTOs can help the most. What was planned to be a 45 minutes presentation ended up taking nearly 3 hours of presentation and discussion.

The recently improved DNV GL standards can be either required or recommended, depending on the subject. Therefore, a number of additional requirements have been developed by Bladena together with a group of WTOs and insurance companies. Not only were the utility companies present. Also, the OEMs (Original Equipment Manufacturers) LM Wind Power and Nordex, ISPs (Independent Service Providers), the insurance company Codan, EUDP (Energy Technology and Demonstration Program) and other parties attended the meeting. This ensured a nuanced discussion influenced by the opinions of all parts of the value chain and is a good example of the progress and maturing that is happening in the wind industry. Beforehand the OEMs, WTOs, insurance companies, etc. operated separately where they now communicate more. From the start, the CORTIR project has been designed to unify and be accepted by the entire value chain in the wind industry. The outcome of the project is a Cost and Reliability Tool (CAR Tool) which is created to minimize the risk and cost associated with blade O&M. The need for this tool is highly relevant as it supports the end-user in planning a cost-optimal maintenance strategy. For this tool to work properly, the value chain needs to cooperate instead of working separately as the data used to develop the tool have to be as reliable as possible. After 20 years in the industry Find Mølholt Jensen, CTO, and founder of Bladena recognizes the changing behavior in the field: “It is good to see that the industry is maturing, and I am proud to have the entire value chain come together to bring down LCoE.” Find continues: “Projects like CORTIR have not only helped us develop highly useful technologies but also changed the way we collaborate within the industry. Our industry was built to make the world more sustainable and it is our responsibility to bring down repair and maintenance cost and increase the lifetime of blades to make the industry become even more sustainable than what it already is.” The CORTIR project is now halfway through its duration. During the two days, Bladena also presented the latest advances within the project for the many attendees. This gave the opportunity for the many partners to give their feedback on what they would like to be implemented and what could be improved. At the end of the seminar, the participants had the opportunity to join a workshop regarding a tip solution or join a wind tunnel test at DTU Wind. The CORTIR project is supported by the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected].

Despite a 50% increase in content, the handbook keeps the same reader-friendly communication format for all curious. Text-heavy technical knowledge is converted into easy to grasp visual language. It is key for communicating the complexity of blade design and function. The goal of the handbook is to be more efficient in communication by creating a shared lingo for the future of the wind industry within blades. For many years the industry has been using many different terms that describe the same topic. Therefore, the Blade handbook is designed to get a common language in the wind industry, to improve the common understanding of everyday blade related issues, and moreover to help newcomers to the industry get an overview. This is achieved by professional, reader-friendly communication design by KIRT x THOMSEN who is specialized in supporting early stage innovation of complex technologies, being experts in making clear, understandable conceptualization and visualization. To ensure the updates are as accurate as possible Bladena and KIRT x THOMSEN have been getting numerous inputs from CORTIR partners from the whole wind industry. Especially, Aalborg University, Force Technology, DIS, Global Wind Service, Guide2Defect, DTU Mechanical Engineering, and DTU Wind Energy have contributed with many important inputs to the handbook. The new CORTIR edition of the Blade Handbook was presented at the latest CORTIR seminar for partners from the whole value chain. Here all the partners had the opportunity to be the first to get the new updated version after a brief history about the development of the Blade Handbook throughout the years. Here the Blade Handbook has been supported by the Danish Energy Technology Development and Demonstration Program (EUDP). The electronic version can be downloaded here. For hardcopy, please contact Bladena. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. Helene Mylenberg (Bladena), Hanne Thomassen (EUDP) and Rune Kirt (KIRT x THOMSEN) are the main drivers behind the new updated version.

According to new research by analysts at Wood Mackenzie (WoodMac), onshore wind farm operators will spend nearly $15 billion on operations and maintenance services in 2019. Of this, 57% ($8.5 billion) will be spent on unplanned repairs and correctives prompted by component failures. Today Bladena successfully hosted yet another seminar within the CORTIR program. Here, one of the principal analysts at WoodMac, Daniel Liu, joined the seminar as a keynote speaker. This resulted in an extremely insightful presentation about the recent research done by WoodMac. The analysts behind the research argue that advanced digital technology such as data analytics and machine learning will enable sophisticated asset management and can help operators optimize maintenance costs. Furthermore, Liu added that there are several reasons why such advanced digital technologies have not been implemented yet, i.e. the obstacle of collecting enough data.“In quite a few cases, the basic economics do not always stack up for digital solutions,” Lui said.

The goal is to investigate the importance of the different uncertainty factors (e.g. probability of detection, weather window, probability of crack propagation) and input parameters as well as finding the right balance between accuracy and viable usability for the end-user. A reason why advanced digital technologies are yet to be used in the field are according to Liu that data analytics platforms need excellent historical datasets to produce quality forecasts and analytics. This can be difficult to obtain, due to organizational hurdles, the time required to digitize, and data management by OEMs and other groups. However, in the CORTIR project, one of the core partners is Guide2Defect, which have collected an extensive amount of data on different blade and failure types for many years. Therefore, it will contribute with the data which the CAR Tool will be based upon. The presentation by Daniel Liu included the possibility for the CORTIR partners to get an answer to their many questions. This lead to a great number of interesting questions and was a foundation for a fruitful discussion for the rest of the day. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. The whole value chain of the wind industry was gathered at the seminar.

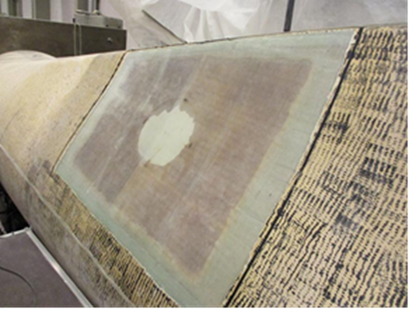

A new project managed by Bladena, called CORTIR, had kicked-off early 2019. The 23 project partners cover the entire value chain i.e. viz. manufacturers (OEM), wind turbine owners (WTO), operational and maintenance, insurance and technology companies as well as two Danish universities that will focus on the research development. The project’s main deliverable is a development of a COST and RISK tool (CAR-Tool) that aims to improve the decision making for operation and maintenance strategies in the wind industry, with the overall objective being to minimize costs and risk. On May 13-14th a two-days workshop was successfully arranged by Bladena as part of a CORTIR project. During the first day at Bladena’s offices, the focus was on the current progress of the project, while during the second day the participants had the chance to visit the structural lab of the mechanical engineering department at DTU, where they could visualize and understand the implications of a structural damage on a blade which is common seen in the field. Figure 1: Photo taken during the 2nd Workshop day at Technical University of Denmark (DTU) visiting the large-scale test facilities in Lyngby. Left: Andrei Buliga from Bladena, Christian Berggreen from DTU and Peder Munkholm Jacobsen from Global Wind Service. The highlighted area on the right picture represents an embedded damage on the blade (face/sheet debonded from core), picture taken during the process of making this damage. During the two days, fruitful discussions and networking were held that lead to a clear consensus between the twenty represented parties. A further development in the level of collaboration throughout the whole value chain will support all partners in the focus of reducing the operational cost (OPEX), maintenance and risk, especially towards structurally related blade damages.

It is common practice that when damages and failures occur on blades, the associated costs for repair actions may end up as a dispute between WTOs, OEMs and insurance companies, as the cost is often not included in the operational budget. Experience from the industry indicates that each player may handle such situations with different strategies. The overall aim of the CORTIR project is to demonstrate how new advancements and understandings can provide a common strategy platform for the WTOs, the OEMs and the insurance companies, always towards the shared goal to reduce the Levelized Cost of Energy (LCoE). The demonstration will be made by using the Cost and Risk Tool (CAR-Tool) which constitutes the main deliverable of the CORTIR project. It is a decision support tool and the development will involve a close dialogue with the entire value chain in the wind energy industry. The project is focused on the financial aspects of the different blades’ defects and how they can efficiently be prevented in order to obtain the optimal maintenance strategy. For further information please visit www.bladena.com , hhtps://cortirproject.weebly.com, and/or contact CORTIR project manager CTO Find Mølholt Jensen +45 53700276 [email protected]. |

Archives

July 2024

|