|

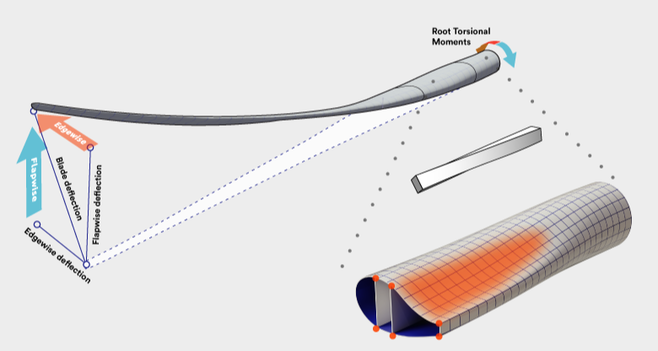

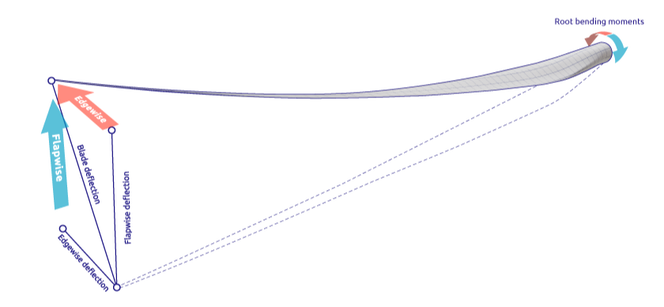

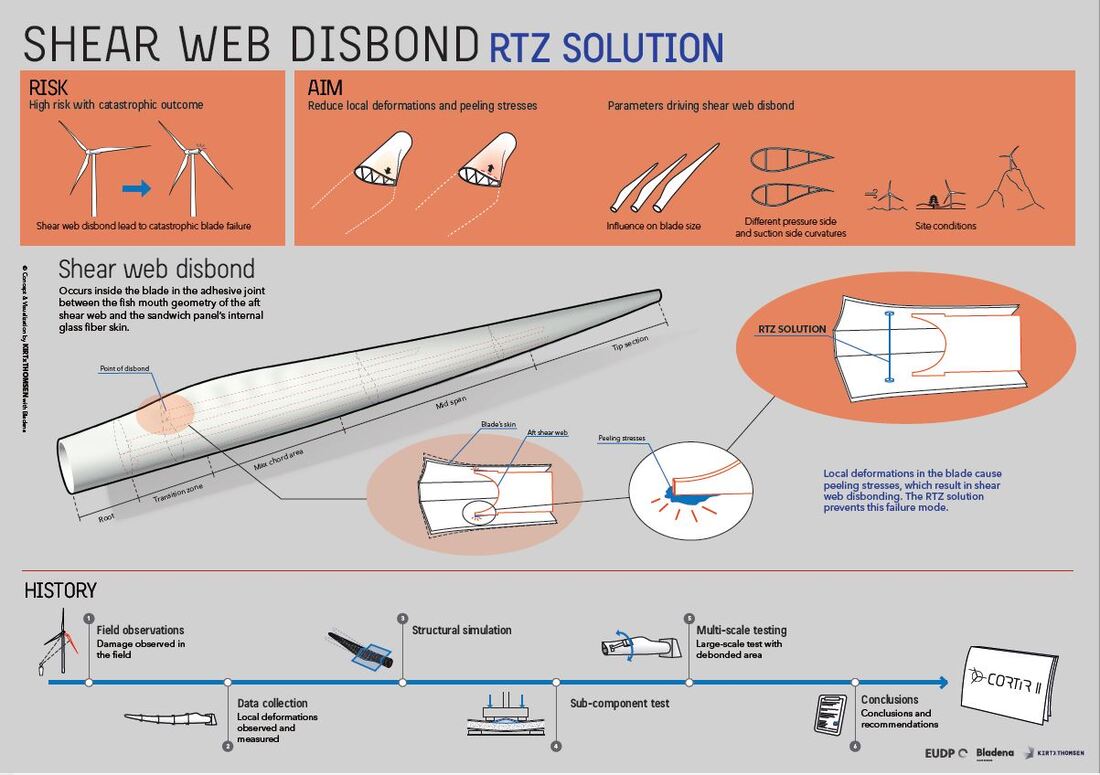

In recent years, wind energy experts have faced significant challenges in maintaining the structural integrity of large wind turbine blades. However, a groundbreaking keynote paper has emerged, offering a comprehensive solution to this problem and equipping wind energy companies with innovative methods to optimize productivity and profitability. This influential paper sheds light on the critical role of torsional loads, which have been identified as a major contributing factor to the growing incidence of structural damages in large wind turbine blades. It highlights the new set of challenges arising from the scaling up of blade sizes without giving due consideration to torsional load components. The increasing concern among prominent wind turbine owners/operators (WTOs) and the recognition of inadequate consideration of torsional loads in testing campaigns by DNV underscore the significance of this topic. Collaborating with esteemed institutions such as Shell, DTU (Technical University of Denmark), and AAU (Aalborg University), Bladena has dedicated the past two years to extensive research on the pivotal role of torsional loads. The paper comprehensively examines the new challenges faced by wind turbine blades, focusing on both experimental and numerical perspectives. On the experimental front, a rigorous large-scale test was conducted at the DTU test facility, while non-linear geometrical 3D FEM simulations were performed from a numerical standpoint. The detailed findings from both approaches are extensively discussed within the paper. A notable highlight of the study is the identification of ever-increasing torsional loads as a potential cause for shear-web and sandwich skin debonding in critical areas of wind turbine blades, including the transition zone and the max chord area. The paper delves into the root causes of failure modes such as CSSD (cross-sectional shear distortion) and breathing (out-of-plane deformation of unsupported panels), which can directly result from applied torsional loads. Furthermore, the paper offers recommendations and suggestions aimed at mitigating the occurrence of catastrophic failures currently observed in the field. These proposed remedies are considered valuable additions to the wind energy industry.

Read the full paper for more information under the following link: https://www.bladena.com/news/innovative-paper-unveils-important-findings-of-torsional-loads-that-will-boost-the-performance-of-large-wind-turbines If you have any questions or comments do not hesitate to contact us on [email protected]. If you would like to hear more, sign up to attend our webinar on the topic on the 14th of July, 14:00-14:30 CEST by submitting the form below. Raising awareness of Torsional Loads impact during operational conditions on wind turbine blades.6/28/2023

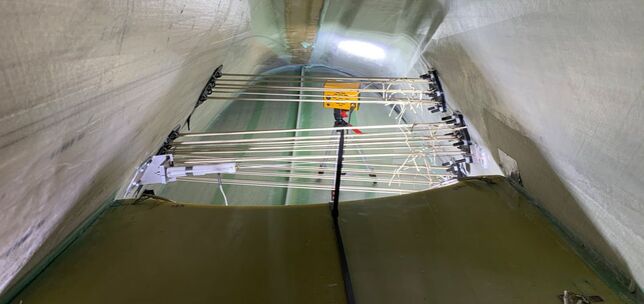

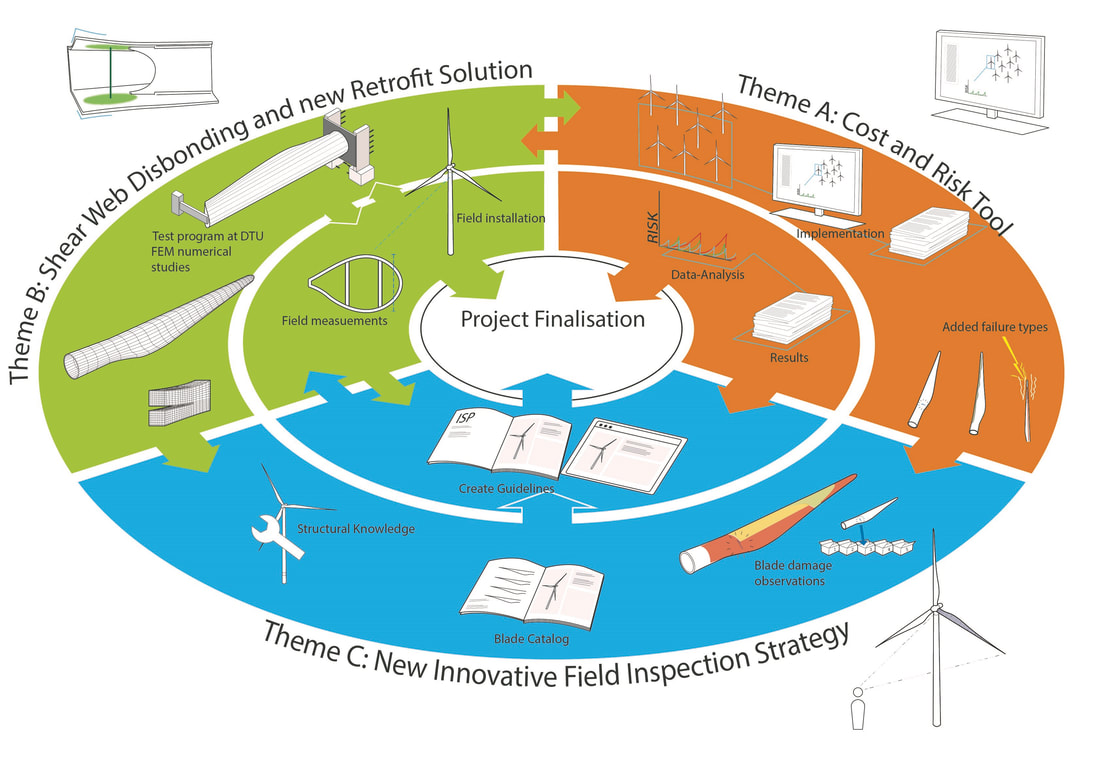

Through a 2-year project called CORTIR phase 2 blade experts from the entire value chain (14 WTOs, 5 ISPs, 1 insurance company, 1 OEM and 2 universities) have worked hard to investigate the impact of torsional loads on wind turbine blades under operational conditions moreover a huge effort was put on tackling these impacts throughout investigating testing standards and regulations, developing a solution to mitigate them and creating maintenance strategies for WTOs. On June 28th, Bladena celebrated with partners the finalization of the project. During recent years, the size of the wind turbine blades has been increasing significantly. For offshore operations the blades length on working wind turbines has reached 60m+ and some OEMs even offer 100m+ blades. With increased blade lengths and growing energy production, the loads on the blades have also drastically scaled up giving rise to more structural challenges. Within the CORTIR phase II project frame Bladena in collaboration with AAU and DTU Construct has investigated the impact of torsional loads on large blades (60m+) these studies showed a significant increase in Root Torsional Moment (RTM) with the scaling of blade length. The torsional moment and the tip deflection under the combination of flapwise and edgewise load components lead to significant out-of-plane deformation in the root transition zone of the blade. This out-of-plane deformation directly causes a significant increase of interlaminar stresses and peeling stresses in the bondlines. The current standards and regulations do not require the application of torsional loads (combination of flapwise and edgewise loads with an offset) during the full-scale test program. By including torsional loads withing the test requirements the risk of critical failure modes in the early stage of the blade’s lifetime would be significantly decreased which would lower operation costs (OpEx) for the WTOs and increase Annual Energy Production (AEP). A multi-scale level test campaign was executed by Bladena and DTU Construct to verify the findings of the FEM (Finite Element Model) numerical analysis regarding the increased peeling stresses in the aft shear web adhesive bondline due to the out-of-plane deformation of the composite panels caused by torsional loads. The tests successfully proved the FEM results and therefore Bladena has developed a product to mitigate the issue. The RTZ Solution™ was developed and demonstrated in different test setups to decrease the out-of-plane deformation in the root transition zone and thereby significantly decreasing the risk of a critical failure mode. Phase 2 of the CORTIR project series focused on finding different ways to ease the pain caused by the torsional loads on large wind turbine blades. Besides the previously discussed findings, a new damage categorization scheme and efficient use of the damage tolerance approach were developed too in order to help the decision-making process of the WTOs.

The final report includes papers made within the CORTIR II project and they can be found in the appendix section of the report. The report with the appendices will be published soon. A great thanks also goes to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program) for funding the CORTIR phase 2 project together with support from the whole value chain in the wind industry with the aim to reduce LCoE. During the period of the project the WTO Blade Network has grown to 55 members, we also would like to say thank you for the members to showing us support and interest towards solving serious issues together. For further information please visit www.bladena.com, and/or reach out to the project manager of the CORTIR phase 2 project, Find Mølholt Jensen, CEO of Bladena at [email protected]. Bladena is proud to announce the appointment of a new Chairman and a new board member. These new appointments follow the company's mission to drive innovation and strengthen its global position in the renewable energy industry. The new Chairman of Bladena is Mr. Jens Egelund-Müller. He brings a solid experience and expertise to the company, in driving a customer focused commercial mindset that will enable Bladena’s future growth, internationally. He has held senior positions in multinational and SME’s throughout his +25Years career and will use his experience together with the executive team to unleash the full potential of Bladena.

"I am honored to be joining the Board of Bladena as Chairman,” says Jens. "The company has a large potential which I am looking forward to support and by widening the understanding of these issues secure a better profitability for wind turbine owners across the world. Not least in a time, where blades are becoming larger and thereby need Bladena's insights and solutions. I am looking forward to working with the team to drive growth and build upon its already impressive journey." Alongside the appointment of Jens Egelund-Müller, Bladena is also welcoming a new board member, Mr. Peter Grabau. Peter brings with him many years of knowledge from the wind turbine blade design and manufacturing part of the value chain, having worked in executive positions at several multinational OEMs. “Bladena has for many years been a company that I have followed closely. Throughout the organization there is a lot of passion for wind turbine blades. They have a unique set of skills that I look forward to digging deeper into, so that we can successfully grow the company even more," says Peter Grabau. Bladena has built its reputation as a Blade Expert in renewable energy, and these appointments are just the latest example of the company's commitment to driving innovation and growth in the industry. With Mr. Egelund-Müller and Mr. Grabau on board, Bladena is well-positioned to continue delivering value to its customers and stakeholders, while also generating sustainable growth and profitability for its shareholders. Used by the entire wind industry all around the world and nominated several times for its excellent communications design the Blade Handbook has become a go-to manual for the industry to use to easier communicate about wind turbine blades. A shared lingo for the future of wind Over the past 7 years, the Blade Handbook has been commonly used by utility companies (WTOs), manufacturers (OEMs), and service companies (ISPs) - amongst others - as the book is designed to improve the common understanding of everyday blade-related issues, to get a common language in the wind industry, and to help newcomers getting an overview. The reason for its success comes down to the collaborations and contributions from blade specialists together with the support from visualization and communication professionals. Developed by experts

To hit a high score in any product or service in any market knowing the end user's needs is essential. In this case, the book started as a document aimed to help all parties involved in a project headed by Bladena named LEX (Funded by EUDP – Energy Technology Development and Demonstration Programme) to get a common understanding of words, processes, levels, and the overall concept. It was clear back then that a shared lingo was needed as a specific blade issue would have many names depending on the eyes looking at it. By teaming up with KIRT x THOMSEN in the concept and design phase with contributions from the partners in the project it was clear that this book started showing great potential. In the following years the visualizations, contributions, and themes were updated in the following projects RATZ, EWIC, and CORTIR resulting in three award nominations and copies shipped worldwide. Gladly, the development of the handbook has been able to continue in the ongoing CORTIR II project – still headed by Bladena with support from KIRT x THOMSEN, partners, and new contributors. What to look forward to in the new edition In the 2022 edition some of the existing content that has been heavily updated are:

”This handbook is a clear result of what happens when companies with different views and understanding come together, building a bridge. By introducing a common language to the wind industry (the value chain) we facilitate the communication around blades,” says Find Mølholt Jensen, CEO, and Founder, Bladena. Editor & contributor: Bladena – experts in structural blade failures providing advisory services and retrofit solutions to lowering the OPEX, risk of blade failure, and loss of AEP to the wind industry. Concept and Design by: KIRT x THOMSEN – experts in visualization, Cleantech, and design with an established and recognized presence within the wind industry and successfully co-developed projects in the markets of wave energy, electric vehicles, smart grid, and in collaboration with public research institutions. Contributors and partners: A great thank goes to EUDP and all partners in the LEX, RATZ, EWIC, CORTIR, and CORTIR II projects together with the ReLife project partners for all their contributions. To download the electronic 2022 Blade Handbook edition, click here. To receive hard copies please contact Bladena at [email protected]. Today and yesterday, 37 companies from the wind industry (14 of them being wind turbine owners) met in Copenhagen and at DTU Wind to discuss risk, risk mitigation & monitoring of wind turbine blades due to the increasing challenges the industry is facing as blades are scaling up. Sensoria™ by MISTRAS Group was invited as a speaker to elaborate on monitoring critical structural failure modes for large blades while Shell, SR Energy, and Ørsted attended a panel to discuss risk-based maintenance and the impact of monitoring. Important topics, considering today’s - and the future - demand for more gigawatts. Monitoring and risk If the industry is to follow the increasing demand for more gigawatts, scaling of blades is necessary and already unavoidable. Therefore, the challenges that modern large blades bring to the market due to minimal structural considerations need to be addressed and taken into account when looking at risk. At the conference, Sensoria by MISTRAS Group and Bladena presented to the entire value chain why continuous monitoring may play an essential role. Adding to this why acoustic emission and loads & vibration monitoring are not only considered to prevent catastrophic failures but also perceived as a source of collecting information for further understanding of damage mechanisms and possible application of a damage tolerance approach. This led to a debate on how this knowledge can be applied in a preventive and proactive risk-based maintenance strategy in a panel with Shell, SR Energy, and Ørsted giving their opinion on this matter. Representing the academia DTU Wind, DTU Construct, and Aalborg University also stated their view on how the above can be used as a methodology to assist risk-based maintenance strategies for utility companies, service companies, and manufacturers. Who was behind the event? Even though both Bladena and DTU Wind are used to hosting seminars and workshops within their respective projects, this was the first time the two made a joint international event open for the entire wind industry. Bladena’s CORTIR II project and DTU’s Relife project (both funded by EUDP) came together to communicate about the effects of risk mitigation and monitoring on blades as both projects are working towards extending the life of blades. Future events In 2023 Bladena will finalize the CORTIR II project where +50 wind turbine owners and operators from the WTO Blade Network and CORTIR II Partners will be invited to attend. To become a member of the WTO Blade Network, please reach out to Bladena. Supported by EUDP A great thanks to the Energy Technology Development and Demonstration Program (EUDP), which is for funding the CORTIR Phase 2 project (Cost, Risk and Transition zone Innovative Reinforcement) together with support from the whole value chain in the wind industry to reduce LCoE. For further information please visit www.bladena.com, CORTIR II or contact CORTIR Project Manager CEO Find Mølholt Jensen +45 53700276 [email protected].

Wind turbine BLADE specialist Bladena allies with Sensoria™ to enhance offshore blade integrity9/15/2022

PRINCETON JUNCTION, N.J. – SEPTEMBER 15, 2022 – Sensoria™ by MISTRAS Group, an innovative 24/7/365 wind blade monitor, is pleased to announce a collaboration with Danish blade specialist Bladena to provide an innovative solution to help maximize offshore wind blade integrity and uptime.

By reducing the need for traditional, manual spot inspections and extending the operational lifetime of offshore wind blades by detecting and addressing the root cause of the damages, the Sensoria™-Bladena collaborative relationship is focused on decreasing wind energy costs related to manual labor, unexpected structural damages, and unnecessary, prolonged blade downtime. This combination will help enhance the generating capacity and annual energy production (AEP) of wind turbines for wind energy owners and operators and contribute to lower operating expenditures (OPEX).

Learn more about the Sensoria™ wind blade monitor at https://sensoriawind.com/. Learn more about Bladena at https://www.bladena.com/. About Sensoria™ by MISTRAS Group Sensoria™— a MISTRAS Group (NYSE: MG) brand — is a 24/7/365 remote rotor blade monitoring system. Using advanced acoustic emission (AE) technology, Sensoria™ continuously detects and reports blade damages to provide Edge-to-Edge Intelligence on wind blade integrity. Developed and manufactured in-house and backed by MISTRAS’ legacy of AE leadership, Sensoria™ delivers real-time damage detection, accessible integrity data through the Sensoria™ Insights Portal, and inspection and maintenance support services through Sensoria™ Dispatch. To learn more, visit https://sensoriawind.com/. About Bladena Bladena is a recognized blade expert on structural damages, specialized in providing advisory services and retrofit solutions on blades. Bladena’s business is based on advanced blade data achieved through many years of field experience and strong collaboration with industrial partners and top worldwide research institutions. They administrate the Wind Turbine Owners (WTO) Blade Network with more than 50 WTOs, as well as several development projects in collaboration with the entire value chain of the wind energy industry, using their expertise to help their customers lower operating expenditures (OPEX), risk of blade failure, and loss of annual energy production (AEP). To learn more, visit https://www.bladena.com/. Download press release here The previous two days 20 companies e.g 11 wind turbine owners, 4 service companies, and DNV met in Copenhagen to discuss OPEX considerations for large new turbines and blades, Standardization and regulations, and inspection strategies at this year’s first CORTIR II Seminar and workshop. The seminar ended with a lab tour at DTU Lyngby to discuss future risk-based maintenance strategies. Furthermore, experimental testing in different scales used in the design and validation phase was a core topic. Panel discussion: OPEX consideration for large new turbines/blades, chaired by Mathias Reding, Bladena. Participants: Signe Lynge Olsson, Statkraft, Birgit Junker, RWE & José Manuel Orza, ENEL. On day 1 the first panel hosted by Bladena represented Birgit Junker (RWE), José Manuel Orza (ENEL), and Signe Olsson (Statkraft). One of the hot topics included the discussion on how the industry will approach today's planning concerning OPEX when the blades and the risk of failures have increased. Previously, blades in terms of OPEX and risk were considered a top 5 out of 10 priorities. Now, it has become one of the most important priorities (top 1 or 2). In the second panel Christopher Harrison (DNV), John D. Sørensen (AAU), Nicolas Quievy (Engie), and Fran García, (ENEL) discussed the standards and regulations in the wind energy industry focusing on the current initiatives for an updated DNV standard to decrease the risk of catastrophic failure on large blades in operation. Christopher Harrison presented the Joint Industry Project (JIP) project headed by DNV and the panel discussed the importance of additional requirements that can decrease the risk and lower the LCoE, such as:

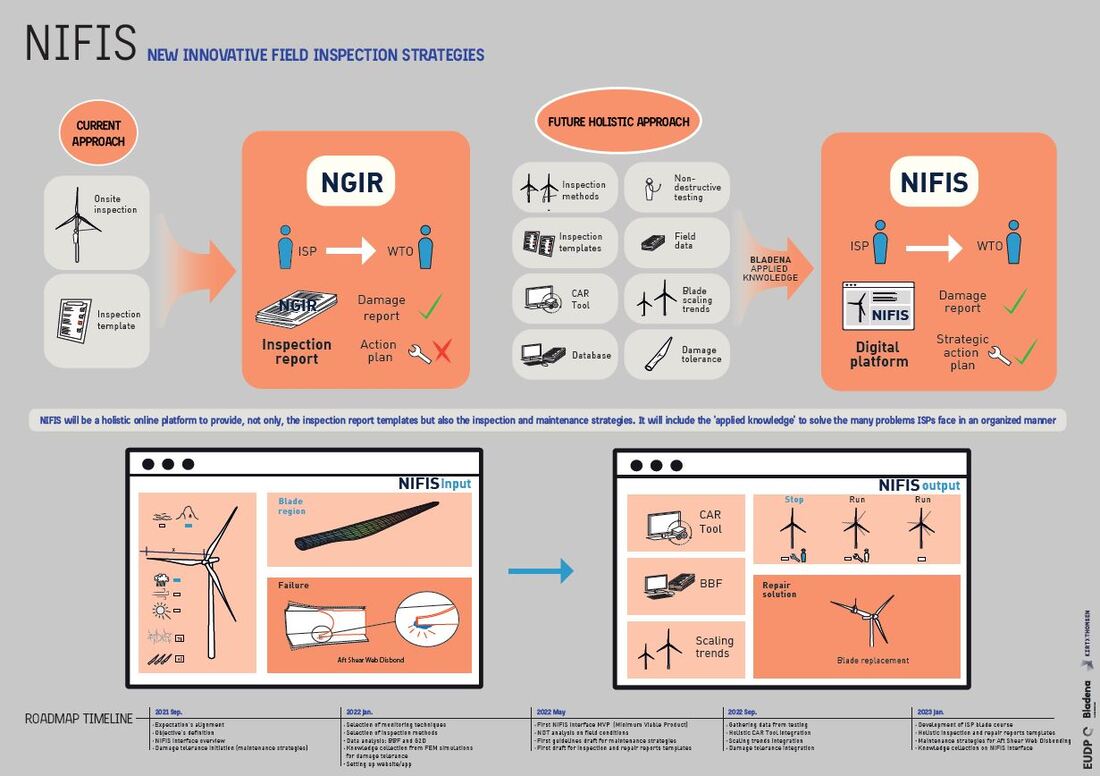

In between these panels, the participants could attend parallel workshops discussing the development of NIFIS. Another workshop during the day was about the standardization and regulation framework focusing on a decreased risk level of blades under operation together with a lower LCoE. The existing framework, as well as the interpretation of the standards, were discussed with the participants. Participants were updated about the current status in standardization and regulation and a knowledge-sharing discussion was initiated among them. As a partner in the project, Wouter Haans from Shell sees great value in attending these seminars: “We are pleased to be part of the CORTIR II project as it creates a platform where we amongst others can discuss the future challenges of OPEX, standards, and risk of large blades in operation” Next week May 19th one more fullday workshop will be held at DTU's main campus where three main topics will be discussed: fracture mechanics, risk-based maintenance strategies, and certification & standardization. DNV will also join this workshop discussing the improvements of the possible standards for different failure modes such as: • peeling in bondlines • interlaminar stresses International open conference in September 2022, Copenhagen +50 wind turbine owners and operators from the WTO Blade Network, CORTIR Partners, and the rest of the industry will be invited to attend. The overall theme of the conference will be WTG Blade Risk Mitigation & Monitoring. To become a member of the WTO Blade Network, please reach out to Bladena. Attendances at this years CORTIR II Seminar and workshop 11-12 of May, 2022 in Copenhagen area at Bladena main office location. A great thanks to the Energy Technology Development and Demonstration Program (EUDP), which is for funding the CORTIR Phase 2 project (Cost, Risk and Transition zone Innovative Reinforcement) together with support from the whole value chain in the wind industry to reduce LCoE.

For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CEO Find Mølholt Jensen +45 53700276 [email protected]. How can you develop wind turbine blades with a stabilizing structure that ensures they last longer and are capable of resisting more forces? That was the objective of Find Mølholt Jensen’s research at DTU Risø carried out for 10 years which led him to establish Bladena in 2011. Now, Bladena has just celebrated its 10-year anniversary on December 19th. By Journalist, Berit Jarmin, Published December 20th, 2021

Ahead of their time

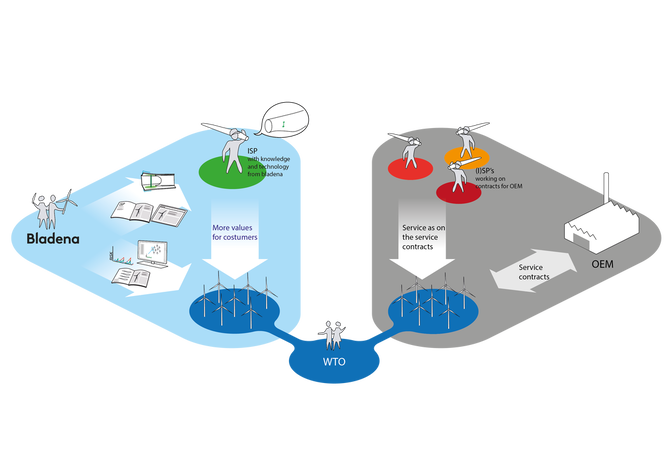

Bladena did not exactly find a goldmine at first with the D-String® not because of the product’s attributes – as it is successfully used globally today – but, because the industry needed convincing on why the wind turbine blades would become prone to structural failures as they grow in size and require structural reinforcement. “When we marketed our D-String® the blades were still primarily produced in smaller sizes that does not require as much reinforcement as the larger ones,” says Find Mølholt Jensen, who wrote a PhD on structural wind turbine blade design prior to establishing Bladena. “Our products and knowledge have materialized now because the forces are bigger on large blades. This has increased the need for repairs as the structural challenges are greater for large blades,” he explains. Transferring knowledge Besides developing products, Bladena’s management and team realized a great need to bridge the gap between the scientific - know-how of blades - and the commercial part of the trade. Therefore, Bladena continuously has extended its business scope and now offers expert advisory services and solutions for the entire value chain – wind turbine owners, operators, service companies, insurance companies, etcetera. In addition, Bladena has led several EUDP projects aiming at developing commercial products that can lower the LCoE, and the company continuously hosts courses and workshops on structural failures and cost optimization for blades in operation. “Through the years we have accumulated an extensive amount of blade data from the entire industry across the world. We use this insight when we for instance perform our Root Cause Analysis or Risk Evaluations which are required to get to the root cause of a blade problem and avoid even more expensive repairs in the future,” Find Mølholt Jensen says. Into the core One of the companies that have benefitted from working with Bladena through many years is ENEL, headquartered in Italy. Their Head of Global Wind Evolution Projects, Francisco García López has engaged Bladena to provide a maintenance strategy for their operations worldwide that has reduced their maintenance costs and the risk of the blades failing in the future. “Bladena is the only company in the trade that looks into the very core of the problem when they analyse mistakes and risks in the blade construction. In my opinion, they are the ones with the greatest knowledge of blade failures in the world,” says Francisco García López and continues, “Besides their unique knowledge of blades they are great people to work with. They are honest and straightforward. If I ever was to hold a position where I would have ownership of erecting a wind farm, I would surely ask Bladena to design the blades,” he says. A life-long mission After 10 years in the business, Bladena now employs 20 people, and the small office in Ringsted has been replaced with a big office in Høje Taastrup, Copenhagen. The company depended on investors for the initial seven years but in the last three years Bladena has been growing independently. “We have found our place in the market helping customers who demand e.g., Root Cause Analysis to find the real reasons for failures. Together we focus on long term solutions that minimize costs and risks consequently ensuring the lowest possible operating loss,” Find Mølholt Jensen says. By extending the lifespan of the blades Bladena is on a mission to make energy from wind turbines more cost-effective and change the way blades are constructed in the future. “Although a lot has happened in the business the past 10 years, our work to reduce LCoE through blade design still stands and have relevance. Bladena will continue to work for that in the coming years,” he finishes. For Danish version click here Yesterday, Bladena and 25 partners from the wind industry kicked off a new EUDP project called CORTIR Phase 2. Uniquely for this project, 5 Independent Service Providers (ISPs) have joined the project to help develop a new software tool and a new retrofit repair solution that will provide ISPs with a competitive advantage in the after-market enhancing their services towards Wind Turbine Owners. The CORTIR Phase 2 project focuses on a critical structural blade issue on +60m long wind turbine blades that will increase in the future. In short, in technical terms, the issue is a debonding of the shear web from the load-carrying spar caps in the root-transition zone meaning that a blade with this type of failure will have a higher risk of a collapsed blade. To foresee and prevent this type of damage Bladena together with 26 partners (15 WTOs, 5 ISPs, 1 Insurance Company, 2 Universities, 1 OEM, and 2 R&D companies) met at the kick-off Seminar on the 22nd of September to discuss the planning and developments of the two main objectives – a New Innovative Field Inspection Strategy (NIFIS) Platform and the development of a Root-Transition Zone (RTZ) retrofit solution. NIFIS – A software tool that helps ISPs determine the best inspection strategy for blade Depending on a crack’s location and size, the blade type, and blade length, to name a few, this will have a huge impact on what actions to take to prevent it from progressing. Based on the situation the software tool will be able to show ISPs what to inspect, and the position. Furthermore, the ISP and/or the WTO will have an instant recommendation on what action to take onsite. In some cases, the recommendation will be to continue running the turbine but do more frequent inspections. By having ISPs to help build the software tool it will become customized to fit their daily practical work taking structural, cost, and risk knowhow into consideration. RTZ Retrofit Solutio Many ISPs only have a limited set of options to offer the WTOs and the competition in the service market is high. The main competitive factor for an ISP is to be able to offer the market a reliable cost-efficient retrofit solution for the increasingly critical damage problems. As of yet, no repair solution has proven more than temporary. Therefore, this failure mode has become a significant risk for the industry, especially for large offshore wind turbines, where limited access may result in the necessity for significantly extended periods of downtime and consequently AEP losses. Through the next 2 years, the aim is to develop and demonstrate an innovative technology of a retrofit solution to a level where it is ready to be commercialized by Bladena after the project period. The RTZ-Solution will fulfill a need in the market and will be uniquely designed for the high forces in the root-transition zone of the blades, removing the root cause of the shear web disbond failure mode and providing more reliable blades for the WTOs. Why call the project “phase 2”? In the previous project CORTIR, a Cost and Risk /decision support tool (CAR Tool) was developed to help WTOs be able to calculate different variations of O&M strategies showing the risk of each strategy. Data simulations from the CAR Tool will be used in NIFIS amongst others. The outcome of the seminar Throughout the seminar, the participants had many relevant questions about how the solutions will be developed in the project. The overall answer was that to ensure the most optimized solutions it is key that the partners bring all their knowledge and expertise to the table. Also, they talked about NIFIS and how the WTOs will be able to inspect blades daily without increasing the OPEX drastically. This will be further discussed and developed in workshops in the next two years.

In the panel discussion the WTO Blade Network Steering Group Members Nicolas Quievy, Engie, and Birgit Junker, RWE debated with partners about the future of blades and how new sustainable blades will become an increasing factor in the future. Bladena has for many years been pushing for the industry to improve the certification standards through Owners Requirements, and also here the panel sees some positive improvements as DNV is working on a project to do exactly this. Even though there were disagreements on how to go around these improvements, there was a broad consensus that if wind turbine owners are not involved in supporting the improvements of the certification standards they should get involved. A great to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (EUDP-program) for funding the CORTIR Phase 2 project (Cost, Risk and Transition zone Innovative Reinforcement) together with support from the whole value chain in the wind industry to reduce LCoE. For further information please visit www.bladena.com, https://cortirproject.weebly.com, and/or contact CORTIR Project Manager CTO Find Mølholt Jensen +45 53700276 [email protected]. Having successfully completed three major research projects (CORTIR, RATZ and LEX), Bladena has been successful to continue the collaboration with EUDP and 27 companies in a new 2-years project called CORTIR Phase II. The partners cover the entire value chain involving 15 wind turbine owners (WTO), 5 Service companies (ISP), 1 Manufacturer (OEM), 1 Insurance, 2 R&D Consultancies as well as two Danish universities.  Partners are: Bladena, AAU Civil Engineering, DTU Mechanical Engineering, Kirt x Thomsen, Global Wind Service, ECC, RWE, Engie, Hofor, EDF Energy, Equinor, EWII, Acciona Energy, Arise, Enel, Statkraft, SSE, Total Eren, Shell, Northland Power, RES, GEV, DanWind Construction, FlexWind, Vent-To, Codan and Nordex. Project deliverables The main deliverables are a new retrofit solution designed for high forces in the Root-Transition Zones (RTZ) of blades, a new innovative state-of the art operation and maintenance strategy and lastly further developments of the Cost and Risk Tool (CAR Tool). Bladena and partners have a budget of 3.2 mill. Euro to deliver the results. As the wind industry is continuously growing, so are the wind turbines. With increasing blade lengths structural failures of the blades become a significantly bigger technical risk as well as financial risk, resulting in increased cost for repair and loss of Annual Energy Production (AEP). One of the most critical structural issues of large +60m wind turbine blades is debonding of the shear web from the load-carrying spar caps in the root-transition zone. This failure mode is today occurring more frequently due to significantly increased fatigue peeling forces in the adhesive bondlines. As debonding of the shear web can fast lead to very critical blade failures, and as of yet no repair solution has proven more than temporary, this failure mode has become a significant risk, especially for big wind turbines, where limited access may result in extended periods of downtime and consequently AEP losses. The RTZ-Solution will fulfill a need in the market and will be uniquely designed for the high forces in the root-transition zone of the blades, removing the root cause of the shear web disbond failure mode and providing more reliable blades for the WTOs. NIFIS will be a New Innovation Field Inspection Strategy developed to be used as a decision support tool. Finally, the Cost and Risk Tool (CAR Tool) developed in house will be used to analyse different maintenance strategies and this will be coupled with field experience and the findings and conclusions gathered in NIFIS, easily accessible and ready to be used by WTOs and ISPs.

|

Archives

July 2024

|