|

Dear Network, We are proud to present a short video about Bladena where our new Sales director Peter Grabau is talking about his core understanding of Bladena and our retrofit uptower solutions. The solutions that Bladena is offering can significantly improve the robustness of the blade, not only towards the torsional loads but also towards other common flaws like wrinkles, poor bonding and others. Let´s make your blades ROBUST together! As previously detailed in the 4th issue of PES Wind Magazine in 2023, Bladena initiated the “Owners Requirements - Phase 2” (OR-P2) project in early 2024. This initiative aims to support the industry towards optimal operational efficiency through collaborative efforts with wind turbine owners (WTOs) and manufacturers (OEMs).

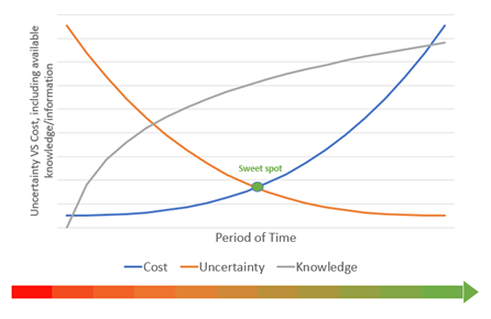

As turbines, and their components such as the blades, grow larger, blade failures in the early stages of their lifetime have raised serious concerns. Ensuring robustness and reliability is essential for optimal operational performance. The primary objective of OR-P2 is to close the gap between current industry blade certification requirements and operational conditions. By challenging the current IEC certification processes, the project seeks optimized assessments to enhance blade quality, robustness, and performance, consequently increasing overall reliability—and improving outcomes for all stakeholders. The OR-P2 project thoroughly investigates current design and testing methodologies, moreover, providing actionable insights. This initiative encourages the industry to implement additional, more representative certification requirements in order to ensure higher blade reliability. So far 8 WTOs have decided to join, namely Engie, Shell Global Solutions, Iberdrola, ScottishPower, SR Energy, TOWII, OX2 and another large WTO who wish to remain unnamed at the current stage. With the support of this very strong WTO group, Bladena has initiated discussions with OEMs, test centers, and certification bodies to seek a common understanding of current requirements, how could we achieve a higher reliability level, and joint ownership of the additional requirements. If you are an Owner or Operator interested in the “Owners Requirements – Phase 2” project, joining the project consortium is still open and we invite you to participate in this initiative. For further details about participation or for more information, feel free to contact Find Mølholt Jensen Bladena's CEO and manager of the Owners Requirements - Phase 2 project at [email protected]. We are looking forward to hearing from you and to having you on board in this potential industry direction-changing initiative! If you have any questions and would like to discuss wind turbine blades with us write to [email protected]  We are proud to share the latest developments in establishing a Technical Knowledge Framework (TKF) under the EUDP (The Energy Technology Development and Demonstration Program by the Danish Energy Agency) funded, CORTIR III project and a corresponding successful online seminar on the 18th of June. The primary objective of the TKF is to streamline the transfer and communication of theoretical knowledge, making it more accessible to the industry. The knowledge framework will be inspired by how it is being done in other industries, such as civil engineering, naval architecture, oil & gas, and aircraft industry. In recent efforts, we have initiated a collaboration between the CORTIR III management; Bladena, Technical University of Denmark – Civil and Mechanical Engineering (DTU Construct), Aalborg University (AAU); and Technical University of Denmark – Wind and Energy Systems (DTU Wind). Firstly, we conducted two sequential meetings with Professor Christian Berggreen from DTU Construct and Professor John D. Sørensen from AAU. During these meetings, we discussed and refined the framework's methodologies and implementation strategies. These sessions ensured that the framework was both comprehensive and practical. This was followed by a technical meeting regarding one of the key tracks, “Materials and Testing”, of TKF, where experts from Bladena, DTU Construct, AAU, and DTU Wind have joined in order to initiate an essential knowledge-sharing process between the participating parties. The next technical meeting is already scheduled to ensure the continuation of the fruitful collaboration between the CORTIR III management group and DTU Wind. Furthermore, we organized a highly successful online seminar for the CORTIR III partners and the WTO Blade Network to which 19 WTOs, 2 universities, 1 ISP, and 1 OEM registered to participate. This seminar provided a platform for discussions, feedback, and presentation of the TKF's potential capabilities. The participation and engagement from the attendees highlighted the seminar's success and the TKF's potential impact on the wider wind community. We would like to say thank you to all of you who participated in the online seminar, and to EUDP for providing a platform for establishing the Technical Knowledge Framework. We look forward to the continued development and implementation of the TKF and more collaborative efforts in the future! We’re happy to announce that we are welcoming four new colleagues to Bladena! As we keep growing, we’re proud to introduce the new team members who has joined us in May and June 2024: Peter Grabau - Peter, has been a Sales Director and a board member at Bladena the last year, and now is responsible for our global sales OEM strategy. With over 30 years of experience in blade technology and a background at LM Wind Power and Envision Energy, Peter has extensive expertise in blade design and innovation. He holds two master’s degrees in engineering and an MBA, making him the perfect fit to lead our sales efforts. Jakob Wedel-Heinen - Coming on board as a Senior Engineer, Jakob’s extensive experience and expertise are going to be invaluable in current and future projects we are involved in. With over 25 years of experience in wind and renewable energy from established industry members such as TÜV SÜD, LM Wind Power, Ørsted, Vestas and DNV, Jakob is proficient both as a senior technical specialist and a project manager. Lorena Mestrovic - Our new Office Assistant! Lorena will be the backbone of our office, making sure everything runs smoothly and efficiently. Evangelos Pallis - Joining us as a Blade Engineer, Evangelos brings valuable knowledge and a fresh perspective to our engineering team. Evan holds 2 master's degrees, one in wind energy and one in environmental engineering, with his strong background his contribution will be significant to both current and future projects. We’re excited about the future and confident that Lorena, Evangelos, Jakob, and Peter will play key roles in our continued success.

Please join us in giving a warm welcome to Lorena, Evangelos, Jakob, and Peter! If you have any questions and would like to discuss wind turbine blades with us write to [email protected]

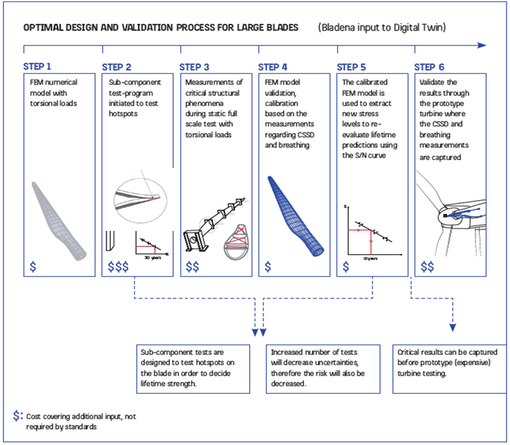

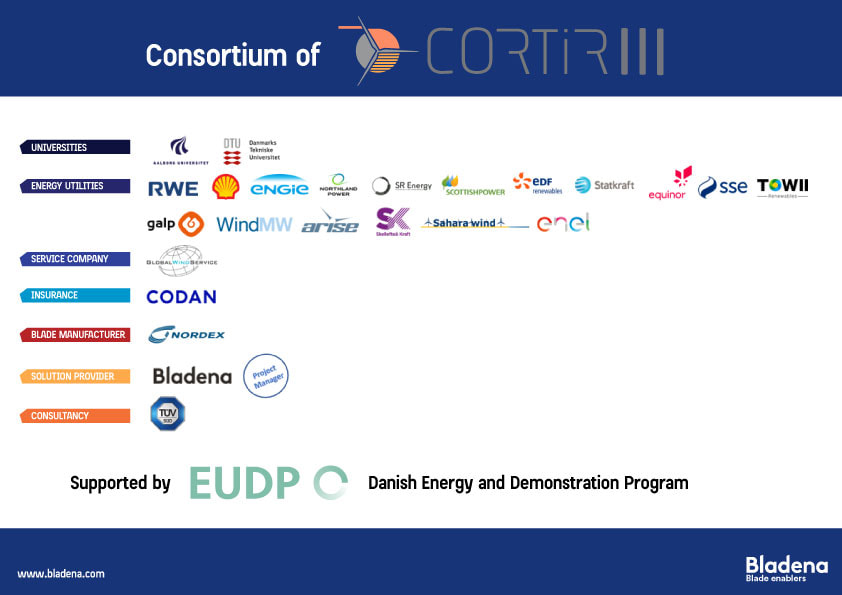

Having successfully completed four major research projects (CORTIR II, CORTIR, RATZ and LEX), Bladena has been successful in continuing the collaboration with EUDP and 24 companies in a new 2-years project called CORTIR Phase III. The partners cover the entire value chain involving 18 wind turbine owners (WTO), 1 independent service provider (ISP), 1 manufacturer (OEM), 1 insurance company, 1 independent consultancy as well as 2 Danish universities.  Partners are: Bladena, AAU Civil Engineering, DTU Construct, Global Wind Service, TÜV SÜD Denmark, Codan, Nordex, Engie, Shell, Statkraft, Northland Power, SR Energy, ScottishPower, EDF Renewables, TOWII, Equinor, SSE Renewables, Galp Energia, WindMW, Arise, Skellefteå Kraft, Sahara Wind, ENEL, European Energy, OX2 Project scope The main deliverables of the project are an innovative trailing edge reinforcement to remove the root cause of trailing edge split failures, a field measurement campaign, a sub-component level test campaign focusing on specific failure modes, a thorough Validation Process, and the application of the damage tolerance approach similar to other industries (civil engineering, naval architecture, aircraft, oil and gas) in order to increase blade reliability. Bladena and partners have a budget of 2.8 mill. Euro to deliver the results within the 2-year project framework. As the wind industry is continuously growing, so are the wind turbines. With increasing blade lengths structural failures of the blades become a significantly higher technical as well as financial risk, resulting in increased cost for repair and loss of Annual Energy Production (AEP). In many cases, the blades’ actual lifetime is far shorter than it is predicted once commissioned into operation. One of the critical structural issues of large (+60m) wind turbine blades is trailing edge splits, frequently for blades with large flatback trailing edge profile where corner bondlines can be found. This failure mode is today occurring more frequently due to significantly increased fatigue peeling stresses in the adhesive bondlines. A field measurement/demonstration campaign will complement the development of the solution. Shell, as one of the management steering group members of the project, will provide an operational turbine to perform in-field measurements, focusing on out-of-plane panel deformation. During the measurement campaign, Global Wind Service and Nordex will support Bladena in the installation of the equipment. Value for partners and the wind industry

The measured in-plane strengths are in such high ranges that it is not possible to experience in-field. As part of the CORTIR III project, a sub-component level test is designed to demonstrate the impact of panel bending on specific failure modes rather than in-plane strength or wrinkles. During the 2-year project period, a large number of whitepapers will be released to further mature the industry which all will be paired with an online webinar free to attend for anyone who is interested. Kick-off seminar and acknowledgement On the 21st of March 2024, Bladena successfully hosted the kick-off seminar for the CORTIR III project. During the event 16 of the partner companies were represented with a total of 25 participants. We would like to say thank you to all attendees of the fruitful seminar and also the partners who could not make it to the kick-off event for their support. A great thanks also goes to the Energy Technology Development and Demonstration Program (EUDP), which is administered by the Danish Energy Agency (Energistyrelsen part of Klima-, Energi-, og Forsyningsministeriet) for funding the CORTIR Phase III project.

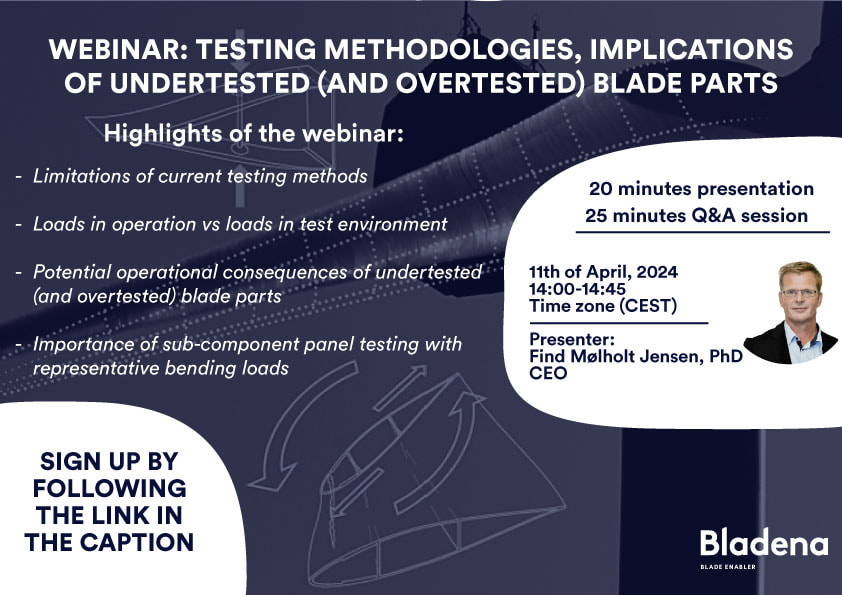

For further information please contact CORTIR Phase III Project Manager, Bladena’s CEO, Find Mølholt Jensen at [email protected]. Based on the previous successes, Bladena is hosting another exclusive webinar, this time with a focus on wind turbine blade testing methodologies. The webinar will be presented by Find Mølholt Jensen, PhD, CEO of Bladena, discussing insights about blade testing methodologies with special attention on the implications of undertested (and overtested) parts of WTG blades. The following points will be the key highlights of the webinar:

As during the previous webinars, Find’s presentation will be followed by a Q&A session, where the participants ask their questions to Find and further discuss specific topics. Here are the practical details of the coming webinar: Date: 11th of April, 2024 Time: 14:00 – 14:45 CEST Platform: Microsoft Teams The participation is free of charge, sign up is available by submitting the submission form below. We are pleased to announce that our application was successful and got approved by @EUDP for a 2-year project, marking a meaningful step forward in our commitment to optimizing the performance and reliability of wind turbine blades.

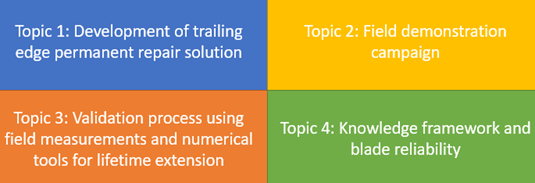

The CORTIR phase III project has a prominent consortium of 22 partners headed by Bladena. The core partners of the project besides Bladena are DTU Construct; Aalborg University Institut for Byggeri, By og Miljø; and Global Wind Service, in addition we have a WTO steering group consisting of RWE, Engie, and Shell Global Solutions International. Besides the above already mentioned, 14 other owner/operators (TOWII, Statkraft, Northland Power, Scottish Power, SR Energy, EDF Renewables North America, WindMW, Arise, Equinor, Galp Energia, Skellefteå Kraft, SSE, ENEL and Sahara Wind), 1 OEM (Nordex), 1 insurance company (CODAN), and 1 independent consultancy (TÜV SÜD Denmark) will be in the consortium. The primary focus of the project is minimizing Operational Expenditure (OPEX) of wind turbine blades and maximizing the Annual Energy Production (AEP) of wind turbines, using a risk-based approach. The project will have 4 main topics:

We believe that, with this project we can take an important step towards more reliable wind turbine blades with extended lifetime, keeping the turbines in operation longer without having to perform costly repairs or in some cases even blade replacement. The whole consortium is excited to begin this project in 2024, as quoted from Tobias Söderlund from Skellefteå Kraft, one of the partners of the project: “It came as great news to us that the CORTIR phase III project has been approved. This strategic collaboration, led by Bladena and supported by a distinguished consortium, underscores our collective commitment to advancing wind turbine blade reliability. Looking forward to a successful project that sets new standards in operational efficiency and blade reliability.” Another project participant, Francisco Garcia from ENEL also added: “We are delighted by the approval of the CORTIR phase III project. Led by Bladena and supported by a distinguished consortium, this strategic collaboration reinforces our shared dedication to advancing wind turbine blade reliability. Anticipating a successful project that will establish new benchmarks in operational efficiency and blade reliability, we look forward to the impactful outcomes ahead." The consortium would like to acknowledge the EUDP (Danish Energy Development and Demonstration Program) for financial support under the grant number: 640232-511715. If you have any questions regarding the project, please feel free to reach out to the project manager, Find Mølholt Jensen at [email protected].

|

Archives

July 2024

|